The APJ DreamLab was instituted at TKM College of Engineering with support from the Kerala Technological University, Government of Kerala and Kerala FabLab. It was commissioned to operate in August 2017 by the then-Principal, Dr. Ayoob S, and was inaugurated by Hon. TKM College Trust Treasurer, Jalal Musaliar and Hon. TKM College Trustee, Haroon Musaliar. The lab aims to be a focal point for innovation in the local community of Kollam district. With over sixty lakhs rupees worth of hardware and working materials, this state-of-the-art facility is indeed a wonderland for anyone who wishes to see his/her ideas come to life. With provisions for 3D printing, CNC milling, Laser engraving and cutting, Electronics work area, Vinyl cutting, and coding, it provides nearly all equipment a fabber would ever want. As with other fablabs, Fablab TKMCE is open not just to students of the institution but to everyone who is zealous about digital fabrication. The lab is part of the fablabs.io network and advocates the concept of “Open Hardware”, where hardware designs are left open to anyone and everyone to use or modify..

CNC Router

The lab houses a desktop CNC router from shopbot. The device does not have a full-sized bed and so can be used medium sized job in wood(hardwood) and other natural or synthetic materials of similar hardness. Designs can be done on any design tool and cutting needs to initiated using the shopbot application. Users are advised to ensure that the documents are in formats compatible with the shopbot application. Users must also ensure that they wear gloves when adjusting or changing the tools. The router can also be used for cutting electronic circuits out of copper boards of varying sizes. Ensure that the size of the tool used matches the required profile.

Vinyl Cutter

A vinyl cutter from Ronald is made available from use at the lab. Vinyl rolls of different color are available in the lab. Job needs to be submitted through the fab module, which is available only for Linux, hence the attached workstation has been configured with Ubuntu. Vinyl will be used mostly for finishing a product with colorful designs or for branding it. The Vinyl cutter can also be used to cut flexible circuits be feed it thin copper rolls.

Sandblaster

Sandblaster is an excellent tool for cleaning and smoothening. The device works by blowing sand at high velocity onto the workpiece. This process is called abrasive blasting and can be used to smoothen out a rough surface or object or clean surface material such as rust from an object. Leaving the lid open poses serious injury risk and care needs to be taken to always wear gloves when using the device. The sandblaster used in the lab is an Econoline sandblaster, the required air pressure to accelerate the sand particles is generated using a high-pressure tire inflating pump. Users must ensure that the pump is operated properly while working with the sandblaster.

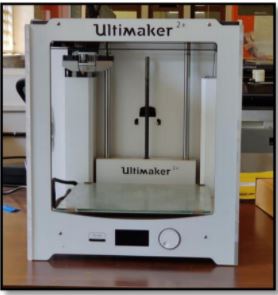

3D Printer

Ultimate 2+ 3D printer is available at the lab. Users should never change the filament or parameters of the machine without informing the lab staff or manager. Ensure the device is connected to a UPS before operation. Although the device can be operated directly from attached workstation, it is advised that the job be given from SD card. Design can be done in the attached workstation, however since only workstation is attached to the 3D printer, it may create inconvenience for other users. Do not turn off the power to the device while it is in operation. The device can take a lot of time to complete a job, and so patience is requested.

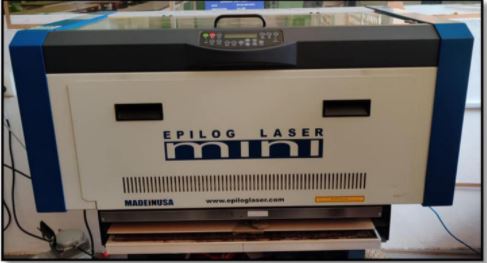

Laser Engraver

A 40 watt laser engraver from Roland is available in the lab. As one of the more expensive and fragile pieces of hardware in the lab, it advised that users do not use it in the absence of lab staff or manager. The device poses fire hazard as the it involves burning the work piece using powerful lasers. Users are advised to use goggles while operating the device and at no cost should anyone open the lid while it is in operation. Users must make sure that the attached oxygen pump and the exhaust pump are switched on while the device is running. Users are also advised to refrain from attempting to clean the lens or any other part of the device in the absence of lab staff or manager.

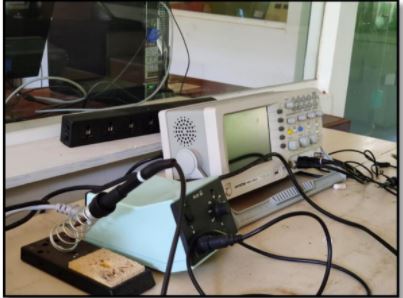

Electronics Work Area

The lab has a host of electronic devices and components needed to make fabricate and test any circuit. Detailed list of all available components, devices and consumables is provided in Appendix 3. Some of these devices may be rented out for a fee, while others may be used free of cost. Any consumable used needs to be replenished by the user within 30 days. Delay in replenishing will invite a fine of 10% of the product cost per week unless under extraordinary circumstances. Soldering poses health hazards and users must take necessary precautions while soldering to mitigate any such hazard to himself or others. Oscilloscopes and function generators should not be taken out of the lab.