Structural Enginnering Lab

The lab mainly facilitates the post graduate students and the research scholars to conduct the experiments related to Structural Engineering, and Concrete Technology. The facilities can be used to test concrete from material scale to structural scale. Equipment such as Proceq Ultrasonic Pulse Velocity Apparatus, Schmidt rebound hammer (Proceq N type), Concrete core cutter are used for the consultancy works (non-destructive testing and structural stability evaluation) by the Structural Consultancy Wing of Department of Civil Engineering.

Schmidt Rebound Hammer test

Schmidt Rebound Hammer test is widely used for non-destructive testing of structures as

per IS 13311 (Part 2): 2013 to provide a convenient and rapid qualitative indication of the

compressive strength of the concrete. There is a specific relationship between the rebound

number R obtained by the impact of the hammer with the test surface and the hardness and

strength of the concrete. The average cube compressive strength of concrete (of size 15 cm) is

then estimated from the selected conversion (calibration) curve printed on the hammer,

depending on the rebound value R and the testing direction (whether tested upwards,

downwards or horizontal).

Schmidt Rebound Hammer test is widely used for non-destructive testing of structures as

per IS 13311 (Part 2): 2013 to provide a convenient and rapid qualitative indication of the

compressive strength of the concrete. There is a specific relationship between the rebound

number R obtained by the impact of the hammer with the test surface and the hardness and

strength of the concrete. The average cube compressive strength of concrete (of size 15 cm) is

then estimated from the selected conversion (calibration) curve printed on the hammer,

depending on the rebound value R and the testing direction (whether tested upwards,

downwards or horizontal).

Diamond Core Drilling Machine

Diamond Core Drilling Machine, HILTI DD 160 is used to cut cylindrical concrete core of

diameter 25 mm – 200 mm from concrete. This equipment is used to extract cylindrical cores

from cubes for preparing specimens for testing water sorptivity and to test the in-situ strength

of concrete by core testing as per IS 516 (Part 4): 2018.

Diamond Core Drilling Machine, HILTI DD 160 is used to cut cylindrical concrete core of

diameter 25 mm – 200 mm from concrete. This equipment is used to extract cylindrical cores

from cubes for preparing specimens for testing water sorptivity and to test the in-situ strength

of concrete by core testing as per IS 516 (Part 4): 2018.

Proceq Pundit PL-200 Ultrasonic Testing Instrument

Proceq Pundit PL-200 Ultrasonic Testing Instrument is widely used non-destructive test

and the best-in-class Ultrasonic testing instrument to evaluate the quality and homogeneity of

concrete. The Proceq Pundit PL-200 is developed using a new generation and design-

protected Touchscreen Unit. The equipment consist of Pundit touchscreen, 2 transducers (54

kHz), 2 transducers (150 kHz), 2 BNC cables 1.5 m, couplant, calibration rod, BNC adapter

cable, power supply, USB cable, DVD with software, documentation, and carrying strap and

carrying case. The instrument is portable and can be used both in lab and in-situ. For material

research, this equipment is used to estimate dynamic modulus of elasticity of cement based

systems based on the ultrasonic pulse velocity, poisons ratio and bulk density. For

consultancy works, this equipment is used to assess the quality of concrete when tested as per

IS 516 (Part 5): 2018. The touchscreen is with highest resolution and sharpest image

available in the market allowing best possible analysis of the measured waveforms. The

machine is calibrated before testing (zeroing of transducer). When the pulse is induced by

transducer (transmitter) at one end, it undergoes multiple reflections through the concrete

matrix and is received at the opposite end (receiver). The velocity (m/s) and time (µs) taken

to pass through the specimen is digitally captured by the apparatus. The instrument has

advanced scan modes such as A-scans, line scans, data logging, and area scans. At present,

the instrument is extensively used by the research scholars in investigating the deterioration

of cement-based materials in aggressive aqueous environments.

Proceq Pundit PL-200 Ultrasonic Testing Instrument is widely used non-destructive test

and the best-in-class Ultrasonic testing instrument to evaluate the quality and homogeneity of

concrete. The Proceq Pundit PL-200 is developed using a new generation and design-

protected Touchscreen Unit. The equipment consist of Pundit touchscreen, 2 transducers (54

kHz), 2 transducers (150 kHz), 2 BNC cables 1.5 m, couplant, calibration rod, BNC adapter

cable, power supply, USB cable, DVD with software, documentation, and carrying strap and

carrying case. The instrument is portable and can be used both in lab and in-situ. For material

research, this equipment is used to estimate dynamic modulus of elasticity of cement based

systems based on the ultrasonic pulse velocity, poisons ratio and bulk density. For

consultancy works, this equipment is used to assess the quality of concrete when tested as per

IS 516 (Part 5): 2018. The touchscreen is with highest resolution and sharpest image

available in the market allowing best possible analysis of the measured waveforms. The

machine is calibrated before testing (zeroing of transducer). When the pulse is induced by

transducer (transmitter) at one end, it undergoes multiple reflections through the concrete

matrix and is received at the opposite end (receiver). The velocity (m/s) and time (µs) taken

to pass through the specimen is digitally captured by the apparatus. The instrument has

advanced scan modes such as A-scans, line scans, data logging, and area scans. At present,

the instrument is extensively used by the research scholars in investigating the deterioration

of cement-based materials in aggressive aqueous environments.

MATEST Unitronic S205N multi speed loading frame

MATEST Unitronic S205N multi speed loading frame (50 kN) is used for testing

mechanical properties of mortar/concrete specimens of smaller size. Loading rates can be

given as input. Flexure testing device E172-02, for 40 × 40 × 160 mm prisms, ASTM C348

and compression testing device E171, for testing 50 mm mortar cubes, ASTM C109 can be

attached to the equipment for testing the flexural strength and compressive strength of mortar.

MATEST Unitronic S205N multi speed loading frame (50 kN) is used for testing

mechanical properties of mortar/concrete specimens of smaller size. Loading rates can be

given as input. Flexure testing device E172-02, for 40 × 40 × 160 mm prisms, ASTM C348

and compression testing device E171, for testing 50 mm mortar cubes, ASTM C109 can be

attached to the equipment for testing the flexural strength and compressive strength of mortar.

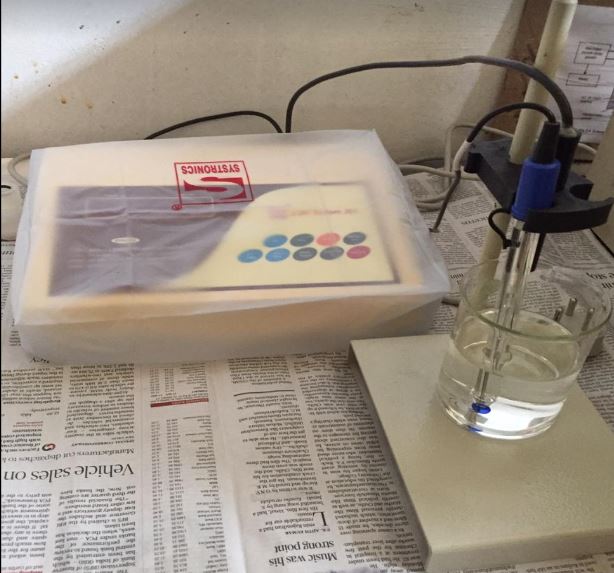

SYSTRONICS Micro Controller based pH System

SYSTRONICS Micro Controller based pH System is a digital pH meter with glass

electrode & temperature probe (Auto Temperature compensation, 3 point calibration,

Resolution 0.01 pH) Type – 361. The instrument is widely used to test the pH of aqueous

solutions, and finds extensive use in the study of leaching behaviour of various cement

systems and alkali activated binder systems.

SYSTRONICS Micro Controller based pH System is a digital pH meter with glass

electrode & temperature probe (Auto Temperature compensation, 3 point calibration,

Resolution 0.01 pH) Type – 361. The instrument is widely used to test the pH of aqueous

solutions, and finds extensive use in the study of leaching behaviour of various cement

systems and alkali activated binder systems.

The other facilities available in the lab are:

- Precise weighing balance (1 micro gram accuracy)

- Digital pH meter (0.01 accuracy)

- Schmidt rebound hammer (Proceq N type)

- Concrete core cutter

- Vacuum desiccators

- Digital weighing balance upto 10 kg (1 g accuracy)

- Flexure Jig for mortar testing

- Compression Jig for mortar testing

- Load Frame (200kN)

- Column Testing Fame (1500kN)

- Compression testing Machine (3000kN & 200T)

- Hydraulic Jack (250 kN & 500 kN)

- Pre-stressing equipments

- Concrete mixers

- Vibrating machine for mortar cubes

- Vibrating table for Concrete cubes

- Needle Vibrator

- Platform Balance(300kg)

- Sieve shaker-Hand operated

- IS Sieves

- Moulds for casting cube, cylinder, beam

- Digital load indicator

- Digital strain indicator

- LVDT

- Air compressor (3HP)

- Flow table

- Self compacting concrete equipments

- Impact test Setup

- Portable Generator

- Electric oven

- VICAT apparatus

Contact Information

Lab in Charge: Prof. Shefeena N, Assistant Professor, Department of Civil EngineeringContact No : +91 9400607655

Email id : nshefeena@tkmce.ac.in

Assistant Lab in Charge:Prof. Thasleen N, Assistant Professor, Department of Civil Engineering

Contact No : +91 94475 03725

Email id : thasleenn@tkmce.ac.in