Plastile: Eco-friendly Composite Tiles

Plastic, once a revolutionary invention, is now an environmental menace. Right? But, as the inventors of plastic, can’t we reverse the menace by transforming it into something useful? Yes, we can. That is what Afzana, Arjun Shankar, Justin Reji, Muhammed Ijas N, and Anu N from the Chemical Engineering department have done by inventing Plastile, a plastic tile made from plastic and metal oxides sourced from industrial leftovers.

What is Plastile?

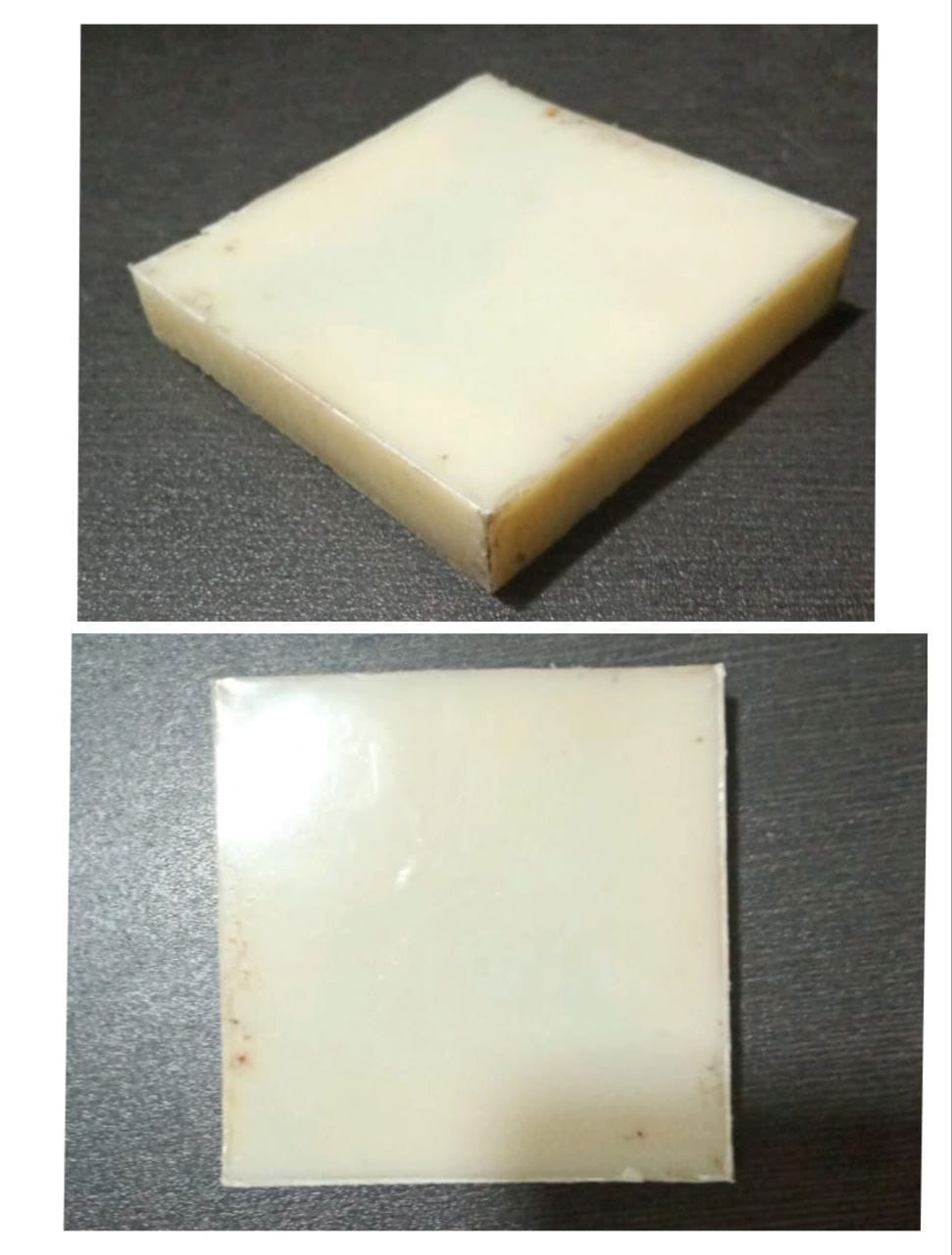

It’s a three-layered plastic tile with a porous metal oxide core that unburdens the heat load on concrete roofs. Its utilisation extends beyond roofing. We can use it as floor tile as well. Without further ado, let’s get to know more about Plastile.

It’s sustainable

As sustainability is the buzzword we cherish the most, Plastile is our expression of sustainability. We built the tile with a separable core and plastic layers that can be separated and recycled. These recycled materials can serve as raw materials for Plastile.

Usually, it is not possible to reuse composite materials. But, the unique design of Plastile allows us to separate plastic and iron. Then, we can reuse both materials as raw materials without any limitations of the end cycle. It ensures eco-friendly resource utilisation. Moreover, Plastile’s composition enables umpteen numbers of recycling. Thus, it not only saves our resources but also embraces sustainability.

It's cool

The large-scale manufacturing of Plastile would be a boon for roofing applications due to its heat-resistant properties. You might be thinking that metals increase thermal conductivity. Then how come Plastile has less thermal conductivity? That is where we tweaked it. We tapped the properties of plastic and metal oxides to increase the thermal resistance.

Plastile is indigenously engineered to reduce thermal conductivity. Plastic and metal oxides have the potential to increase the thermal resistance. Hence, a perfect amalgamation of metals into plastics enhances heat resistance. Thus, the harmonious blend of metal and plastic resulted in the creation of a material with very low thermal conductivity.

As a result, unlike traditional roof tiles that absorb and release heat, Plastile ensures thermal insulation. Thus, it reduces the temperature in concrete buildings. The porous metal oxide core is covered by layers of plastic to maximise the thermal resistance. Hence, Plastile gives respite from the scorching heat and you can count on it as the solution for temperature control.

Waste materials are hidden treasures

Nothing is wasted as long as you know how to turn it into something useful. In line with this thought, we focused on recycling waste materials for the creation of Plastile. Accordingly, most of the components we use in Plastile are waste materials. We sourced and reused industrial wastes like silicon dioxide (SiO 2 ) and ferric oxide (Fe 2 O 3 ) from iron oxide slurry. Further, any plastic material can be used. Moreover, beyond durability, the recycling potential of Plastile reduces the demand for new raw materials. Thus, we have achieved the perfect balance between innovation and conservation.

Gone are the days of wear and tear

As time unfolds, wear and tear become inevitable. Hence, designing materials that stand the test of time is crucial. That is why we used the unique combination of silica (SiO 2 ), iron oxide (Fe 2 CO 3 ), and polyethylene foam. This combination holds the potential to work against corrosion.

Light and Strong

We made it light. But we made it strong too. The lightweightness of the tiles makes the installation easier. Similarly, strength and durability ensure timelessness.

Cost-effective manufacturing

The production cost is very low due to affordable raw materials. Besides, the manufacturing process is simple with minimal energy requirements. As a result, it is a commercially viable option for sustainable and budget-friendly roofing.

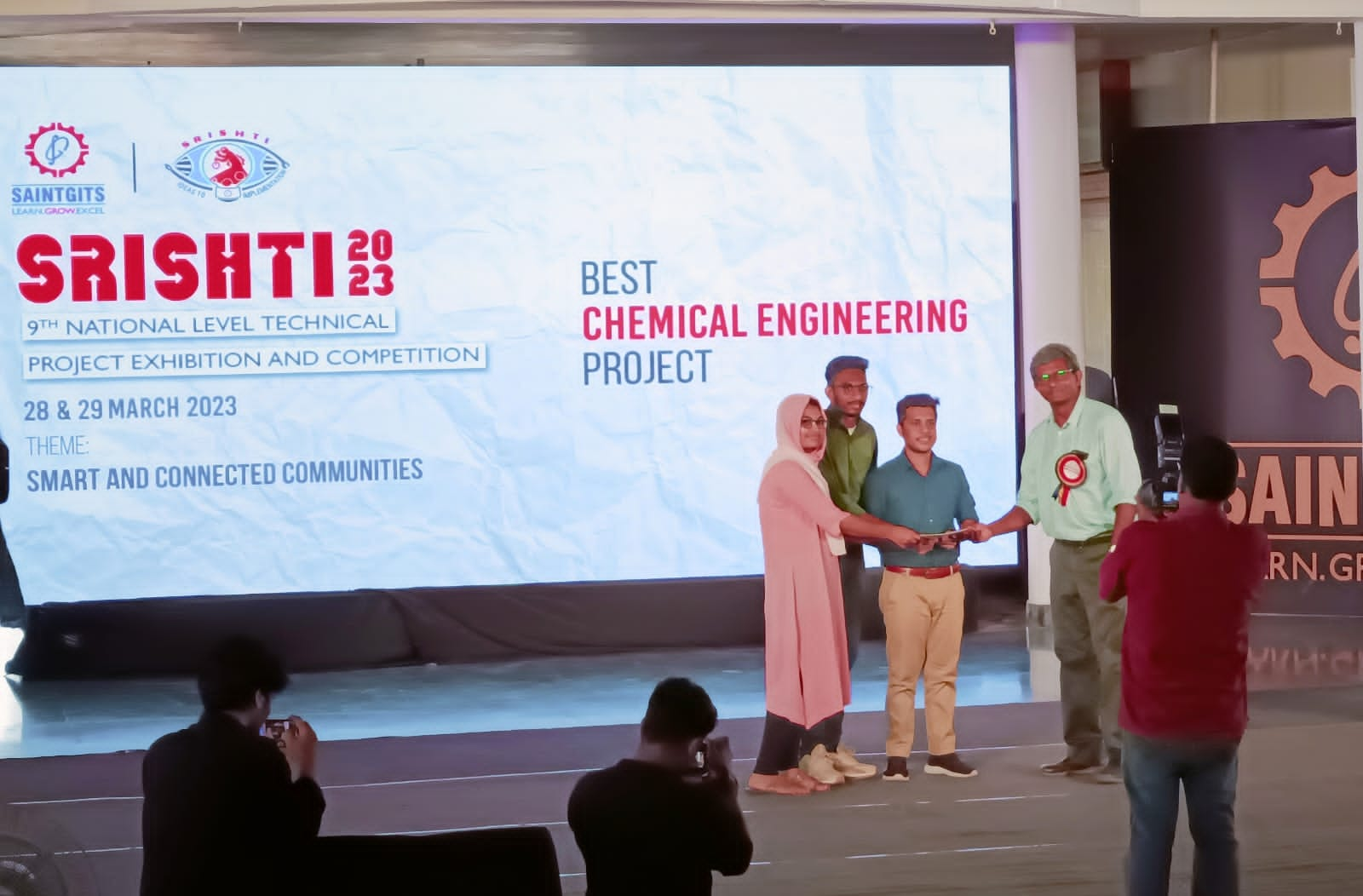

We wrapped up with a new beginning

Years of hard work finally bore fruit with the patenting of Plastile. Besides, we received awards for Best Socially Relevant Project and Best Chemical Engineering Project in SRISHTI '23, 9th National Level Technical Project Exhibition & Competition organized by Saintgits College of Engineering, Kerala. Plastile is our way of giving back to society. This invention is a testament to the possibility of having sustainable and eco-friendly alternatives. Moreover, anyone can access this sustainable option without straining their wallet.